Process of Setting Up a High Tunnel System

Layout of a High Tunnel

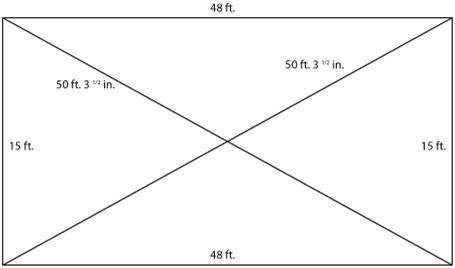

Pythagorean's Theorem:

a² +

b2 =

c2.

Video on laying out the tunnel to begin construction.

Ground Posts

Material: 6-ft, 14-ga, 1 5/8-in. galvanized steel.

Purpose: Permanently hold the tunnel with minimal movement and/or damage from weather and other natural incidents.

- Set corner posts, mark at 3 ft, and install using a torpedo level.

- Run string and fabric tape down the length of the tunnel.

- Finish installing the remaining ground posts.

Video on driving corner ground posts.

Video on driving posts to the line.

Baseboards

Material: 2 × 6-in. pressure-treated lumber (minimal warping and splitting). Note, if the farm is certified organic, nontreated lumber is required.

Purpose: Structural stability for the tunnel, used as a good barrier from surroundings and to stop wind from entering under the side walls.

- Offset to where junction is not at bow.

- Attach to ground posts with a carriage bolt, starting on the inside of the tunnel, with the drill.

- Toenail wood screws at every junction.

- Cut ends to be flush with outside of end wall bow.

Video on installing baseboards.

Bows

Material: 18-ga, 1 3/8-in. "top rail" galvanized steel.

- Set bows in ground posts.

- Attach two self-driving screws to secure the bows to ground posts.

Video on setting up bows or "hoops."

Hip Boards

Material: 2

× 4-in. pressure-treated lumber (minimal warping and splitting). Note, if the farm is certified organic, nontreated lumber is required.

Purpose: Structural stability for bows, used for wire channel and to hang gutters.

- Considerations: Will there be gutters attached for water catchment? Slope is necessary for water flow to catchment tanks.

- Mark 5 ft from ground on all four corners of the tunnel and run a very tight string. The bottom of the board will sit right above this line to make sure the hip board runs straight all the way down the tunnel.

- Same as for baseboards, except that the board is attached to the bow instead.

Video on installing the hip boards.

Ridge pole

Material: 18-ga, 1 3/8-in. "top rail" galvanized steel.

Purpose: Structural stability and to hold bows together. Protection from wind and snow.

- Hang with rope every few bows to make attaching it to the bows with the pipe strap easier.

- Attach (bend out) the pipe strap to one end-wall bow.

- Measure and cut a piece of pipe to reach end-wall bow.

- Pipe strap to all bows (two self-driving screws only).

- Look at broad side and straighten bows.

- Lock in all pipe straps, with third self-driving screw attaching it to the ridge pole.

Video on attaching the ridge pole.

Purlins

Material: 18-ga, 1 3/8-in. "top rail" galvanized steel.

Purpose: Structural stability for bows.

- Prehang cross connectors every two bows (more or less) to rest on top of the hip board.

- Mark at 7 ft from low side of end wall (if on slope) and mark other side at level.

- Hang purlins from cross connectors (finger tight).

- Level out by looking down the length of the tunnel and adjusting it to look "straight."

- Lock down with driver.

- Attach pipe strap at all other bows.

Video on attaching purlins.

Rafters/Cross Brace

Material: 18-ga, 1 3/8-in. clamped and dog-eared galvanized steel.

Purpose: Wind bracing and resistance to snow load.

- Hang from every two bows with brace bands, use a torpedo level.

- Tighten down with bolts facing away from the plastic.

Video on setting the cross brace.

End Wall

Material: 2

× 4-in. and 2 × 6-in. pressure-treated lumber.

- Hang header board to sit above the purlins, installing carriage bolts toward the inside of the tunnel.

- Attach baseboard.

Video on framing the end wall.

End Wall (with Door)

Material: 2

× 4-in. and 2 × 6-in. pressure-treated lumber.

- Hang header board to sit above the purlins.

- Measure center on the baseboard and measure 42 in. in direction where door will hang closed.

- Level verticals for door, dig and/or cut.

- Cut baseboard to proper length.

- Install baseboard and verticals.

- Hang door channel; place it in the center of the vertical on the header board to slide open fully.

- Hang door; level and install stoppers on door channel (we use two self-driving screws).

Video on installing the end wall with a door.

Wire Channel

Material: Aluminum U-channel.

Purpose: Hold main sheet of plastic to the tunnel.

- Start 1.5 in. in from edge of hip board and stop at other end of tunnel, leaving 1.5 in. from edge.

- Run at top of hip board.

Video on installing wire channeling.

Main Sheet of Plastic

Material: 6-mil Tufflite UV-resistant plastic.

Purpose: To keep plastic from ripping while pulling sheet and from wind and natural friction against frame.

- Attach duct tape to all wire channel junctions and rough edges: purlins at end walls; angle of header board on end walls; where bows meet ground posts.

- Throw one rope on each end from one side of the tunnel up and over the ridge pole to the other side of the tunnel.

- Roll out plastic down broad side of tunnel and cut with 1-ft overhang (total).

- Attach plastic to ropes (one at each end of the tunnel).

- Pull all the ropes at one time, make sure the plastic doesn't get caught on any sharp item on the frame.

- Attach "square" at end wall without the anchor set up with wiggle wire in the wire channel. This can be achieved by looking at the natural creases or number that come with the plastic.

Video on pulling the main sheet of plastic over the high tunnel.

Set the End Wall Up to Make the Plastic Tight (Length of Tunnel)

Purpose: Make plastic tight and snug against the frame of the structure. This will keep the plastic in good condition for a longer time.

- Use truck (or other structure) at the end wall and attach to ratchet straps, tennis balls, and rope.

- Attach tennis balls and ropes and ratchet straps at three points on the plastic: one at the ridgepole, one at each hip board, and tighten down.

- Start with wiggle wire on the end wall without truck one 4-ft piece at a time, then move to two 4-ft pieces at a time, all the way to the other side of the tunnel.

- Loosen ratchets and attach wiggle wire at end wall.

Video on securing the main sheet of plastic to the high tunnel.

End Wall Plastic

- Cut a 10-ft piece to fit entire end wall (1 ft longer than height of the tunnel).

- Start at peak and work one way with the wiggle wire (with partner at bottom wire channel moving with the person at the peak.

- Trim excess plastic about 4 in. from the wire channel.

Note, it is important to pull the plastic as tight as possible, with minimal wrinkles, for longevity.

Video on installing end wall plastic.

End Wall Plastic (with Door)

- Use same process as for other end wall.

- Wiggle in door after end wall peak and base board have been wiggled in.

- Trim excess plastic about 4 in. from the wire channel and inside door frame.

Video on hanging the door.

Roll Up Sides

Material: 18-ga, 1 3/8-in. "top rail" galvanized steel.

Purpose: To keep roll up sides snug against the tunnel and to keep sides from flapping in the wind.

- Cut pipe with a 3-in. overhang on end without door and a 2-in. overhang on end where crank handle will be attached.

- Attach fabric clips at every other bow and cut excess.

- Attach crank handle on preferred end of the tunnel using a self-driving screw.

- Install rope hooks and eyebolts on every other bow, making a zigzag where the rope will attach to the tunnel to keep roll up sides from flapping in the wind.

- Attach rope on all eyebolts first, then attach to the rope hooks, and tie off at the end rope hook (should be at hip board right next to the end wall).

Video on installing the roll up side pipe and clips.

Video on installing the roll up side crank handle.

Video on installing rope hooks and webbing.